The Future is Now: The Power of AI Built into Custom Orthotic Fabrication

When prescribing custom orthotics for patients, precision and design are everything. To get optimal results, your orthotics need to fit the needs of your feet and ankles perfectly—not to mention fit easily inside any pair of shoes and hold up to daily wear and tear.

Our office is thrilled to use Go 4-D orthotics. For the first time, we can capture exact, real-time data as you walk and move, and use it to produce a 3D-printed device that far exceeds any other orthotic product.

Want to know more about how it works?

How Go 4-D Revolutionizes Our Orthotics Process

Traditional orthotics are made based on a mold of a patient’s feet using messy plaster or foam boxes. Some practices may create a digital model, but that only provides one piece of a comprehensive puzzle.

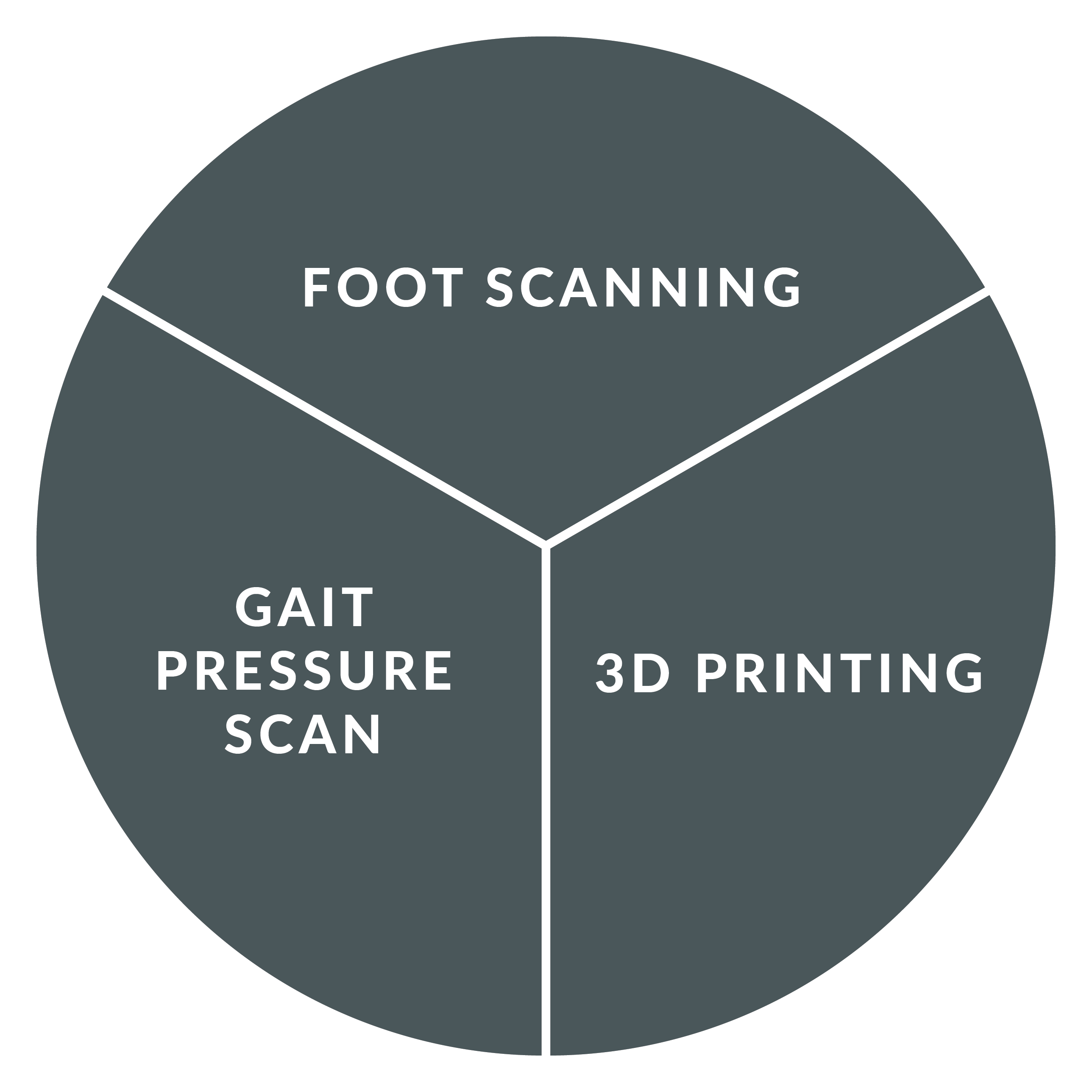

Now, Go 4-D and the precision of HP equipment completes the puzzle for making custom orthotics.

Go4D Orthotics complete the puzzle for great custom orthotics.

A Precision Image as You Stand

When analyzing a patient’s feet for custom orthotics, we use a high-resolution, medical-grade 3D laser scanner. This allows us to create an unprecedented 3D scan of each foot and lower leg right in our office

Real-Time Pressure Scanning as You Walk

A digital re-creation of your foot is a great tool, but combining this with how you walk is even more important.

The Gait Plate has more than 40,000 sensors built into it, providing a detailed picture of how your weight is distributed as you walk.We use this data to understand how your foot needs to be corrected to its optimal position. Find trouble spots, and learn how we can shape your custom orthotics to mitigate these problems.

Creating the Most Technologically Advanced Functional Foot Orthotic EVER

- The honeycomb lattice structure of the 3D printing allows for dynamic and customization of each foot.

- The software provides thousands of data points which allows Dr. Melhuish to generate a precise prescription with control increments of 1mm and 1 degree.

- Five zones under each foot creates the perfect stiffness, flexibility and dynamic control as opposed to traditional methods when orthotics are made from a solid piece of graphite or plastic with a uniform thickness.

- The power of AI built into a custom orthotic fabrication. Variable stiffness and direction of the honeycomb lattice allows dynamic correction of the foot throughout the gait cycle.

HP 3D Printing in the USA

HP 3D printers take the electronic data sent from Dr. Melhuish and turn it into a unique one-of-a-kind device for you.

A Greener Method of Making Orthotics

The benefits for our patients are clear, but Go 4-D is also a brilliantly more efficient and environmentally friendly alternative to prior fabrication methods.

Go 4-D orthotics:

- Require NO use of casting boxes or plaster molds to dispose of.

- Eliminate the need to ship foot molds to the printing center, as all instructions are sent digitally. This cuts the carbon footprint costs of shipping in half.

- NO waste in the fabrication process as the orthotic devises are made directly from powder nylon beads.

The Next Level of Custom Orthotics

With Go 4-D and 3D printing technology, we offer our patients the best custom orthotics ever.

If you would like to learn more about how custom orthotics can help you, please don’t hesitate to contact us! We’ll be happy to help you find the solutions to your foot pain, whether that turns out to be custom orthotics or other forms of treatment.

Give our Carson City office a call at (775) 783-8037 to schedule an appointment with us. If you prefer to reach out electronically, fill out our online contact form and a member of our staff will respond to you during our standard office hours.

Get In Touch

Address

2350 South Carson St

Suite 3

Carson City, NV 89701

Contact

Call: (775) 783-8037

Fax: (775) 782-3787

OPT-IN To Text:

By texting our office at

(775) 783-8037 from your mobile phone, you are consenting to receive SMS text messages from our staff. Reply STOP to unsubscribe.

*Read our Privacy Policy & Terms and Conditions.

Social

© Sierra Foot & Ankle. All Rights Reserved. Privacy Policy.

Web Design by CP Solutions. Marketed by VMD Services.